|

History |

The Whittier wood legacy begins nearly 150 years ago when, in 1867, Charles Whittier was hired by Uncle Ed Brackett to manage the newly formed E.L. Brackett Lumber and Coal Company. As the Farmington, Minnesota business grew, so did the Whittier family. Charles’s son Leon often accompanied him to the worksite, so when Leon graduated from high school, he followed his dad’s footsteps and went to work at Brackett’s. Soon thereafter, Leon was asked to manage the company’s lumberyard in Castle Rock, Minnesota.

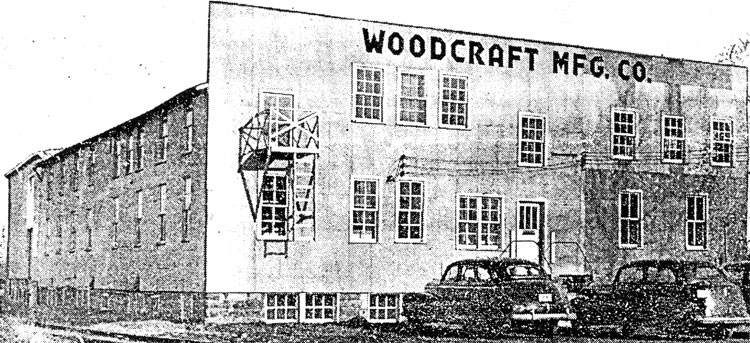

Early on, Leon showed an entrepreneurial side. In 1921 he built a small space in one of the rear lumber sheds at Brackett Lumber in Castle Rock and started the Woodcraft Manufacturing Company. In that small enclosure he built hayracks, screen doors, footstools and even an outhouse for a local bank. Six years later Brackett’s was sold, so Leon moved back to Farmington where he found a warehouse large enough to accommodate his growing business. There, Leon built KD (knock-down or ready-to-assemble) Oak drawing tables for the Federal Art School. In 1932, the company expanded by also manufacturing wood cabinets and desks for Macy’s and other large department stores.

The US officially entered WWII December 8, 1941. Consequently, business, raw materials and able-bodied employees were scarce so the Woodcraft plants shut down for a few years. At that time, most young men went into the service, and the Whittier boys were no exception. Bob entered the Coast Guard and Gordon joined the Navy. Gordon wanted to become a pilot, but because he needed glasses to correct for 20/20 vision, he wasn’t able to travel that path. Instead, good grades in math and science opened doors to Purdue and Notre Dame where he learned how to teach electrical engineering to Navy cadets.

1945 was cause for celebration. WWII officially ended and Woodcraft resumed full scale operations. Also that year, Gordon married Ginger, his high school sweetheart. Like most newlyweds, they threw themselves into building their lives and family.

Gordon and Bob ran the Whittier Molding company as partners. During the day they operated machinery and at night balanced the books. One of their common goals was to rid the company of waste, whether it involved time, motion, materials or money. Gordon invented and patented several machines that improved ways to work with wood. One invention was an electronic lumber thickness gauge that tripled production at their plant while cutting costs by 90%. After it was patented, this particular gauge was widely accepted and used extensively in the softwood lumber business. The Whittiers were the first major producer of pine fingerjointed moldings. This tremendously improved the yield from the Knotty Pine lumber. Another way the Whittiers reduced waste was by recycling materials long before it became an accepted business practice. Not only were they ahead of their time by recycling, but they also believed in a progressive managerial style that influenced everything in the company. At the very heart of this system was the maxim, “Treat others as you would have them treat you.” They had faith that happy, satisfied workers helped create better product, better work conditions and better customer service.

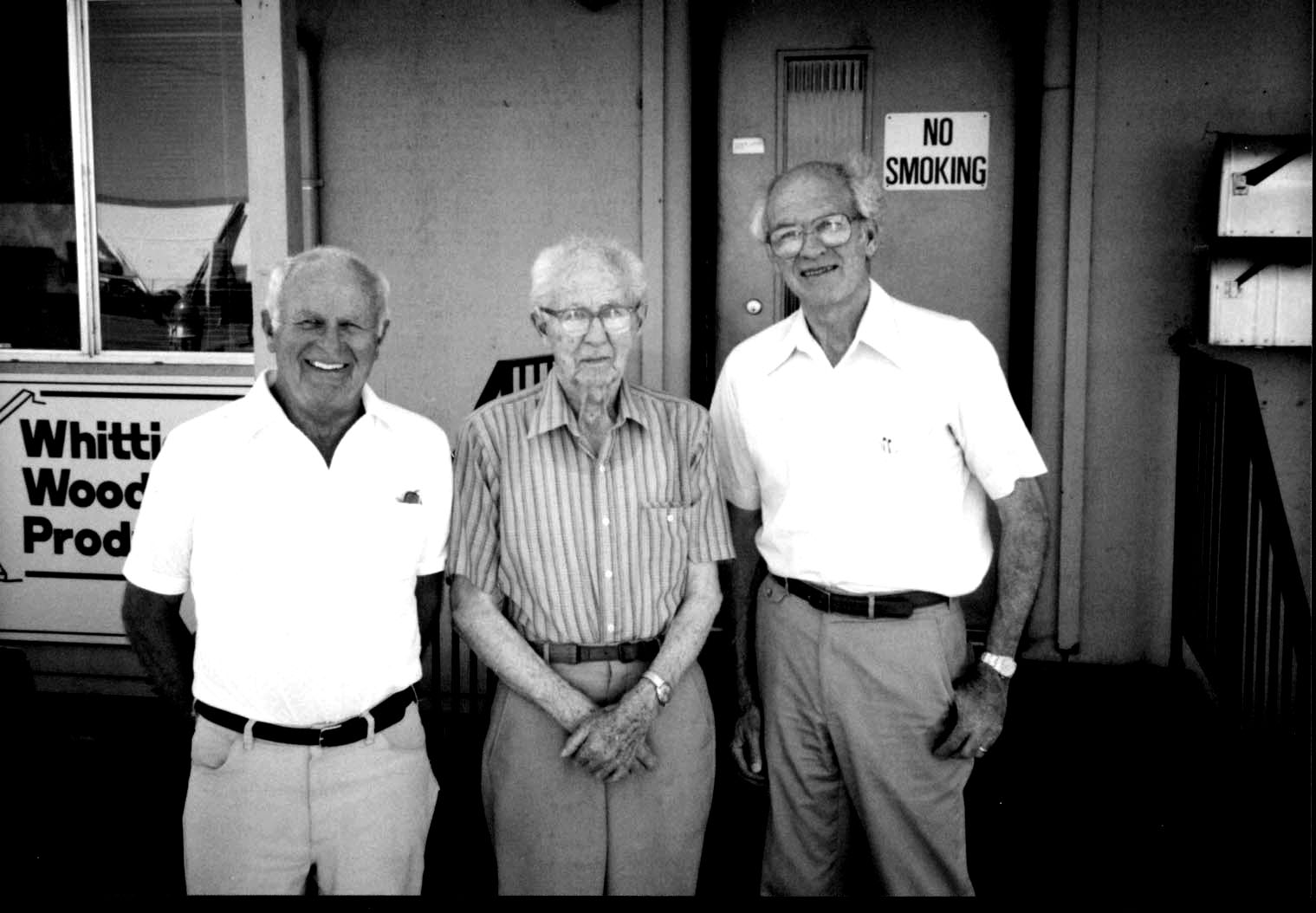

By the early ’70s, two of Gordon and Ginger’s six children had moved to Eugene, Oregon. Longing to live closer to their kids and grandkids, Gordon and Ginger relocated there as well. Being an entrepreneur and not satisfied to sit still for long, Gordon searched for an outlet for his boundless energy and passion for wood. He found it in a small but struggling manufacturing company that made furniture components out of American Alder hardwood. So in 1975, he purchased the business and Whittier Wood Products was born. Because he was a visionary and experienced lumberman, Gordon could see that Alder’s beauty, fine grain and ability to mimic more expensive woods made it an excellent material to use in fine furniture.

Gordon hired his son-in-law, Evert Slijper, and placed him in charge of sales. Due to a lot of hard work and a couple of opportune encounters, business blossomed from making chair components into a Ready-to-Assemble (RTA) and Ready-to-Finish (RTF) furniture manufacturing company. At first, unfinished solid wood furniture stores made up the bulk of Whittier’s customers. But over time, their clients included most of the nation’s major home improvement retailers and hardware stores.

In 1980, Gordon’s son Scott joined the company. Just as his dad had helped out at the New Jersey plant, Scott pitched in where he was needed in Eugene. And through the years, Scott also learned the daily ins and outs of the business. In the early 1990s, Gordon turned the family business over to Scott and Evert. It was a good decision, because thereafter, Gordon was free to focus on his family and faith, two constants in his long, rich life. In 2005 he passed away peacefully, leaving a legacy of loving memories and enduring values.

Whittier Wood has grown quite a bit since its humble beginnings in 1975 as an American Alder furniture component manufacturer. Even though over the years Whittier Wood has changed and evolved, one thing that has remained constant is the company’s commitment to producing high quality real wood furniture.

As the Whittier family heritage of integrity, quality, honesty and delivering on promises endures, Whittier Wood Furniture continues to grow, adapt and change to best serve its customers.